SYSCHEM CONTROLS Products offers a range of standard and custom designed engineered products for all fluid handling industriesThe range of products includes Basket Strainers Bag Cartridge Filters Pig Launchers and Receivers ASME code vessels and many associated process productsIn addition to the range of our manufactured. Pig launcher-Receiver discharge 9 3 PIG TRAP CONSIDERATIONS The design of a Pig Launcher Receiver unit must consider the specific application to handle.

Safe operation on pig launchersreceivers The use of pig launcher and receiver stations for pipeline cleaning inspecting and maintenance is a method seen world wide.

. Mento designs and supplies pig launchers and receivers as a single equipment or. Pigging in the maintenance of pipelines refers to the practice of using pipeline inspection gauges or pigs to perform various operations on a pipeline without stopping the flow of the product in the pipeline. Subsea Pig Launcher Design Standards.

Pig inlet outlet and oil air or water inlet shall be connected respectively to the main pipe by valves. Receivers or traps are vessels installed on the pipeline that allow for unloading of pigs. FES Subsea Pig Launchers Receivers Pressure range to suit client application Designed in accordance with international codes of practice including PED requirements and CE marking Design codes include PD5500 ASME VIII B313 and B318 Suitable for deep water applications depths up to 2000m.

Design codes rating. The drawback is that it is also a high risk event. We offer many configurations including horizontal vertical or sloped ranging from a simple launcher and receiver to complete skid mounted units with all valves and associated piping.

For connection between Launcher Receiver and pipe refer to pigging operation flow diagram. Pig Launcher and Receiver. The pig launcher and receiver or trap is designed according to subsea codes and standards given by the operator.

Has extensive experience designing and fabricating Pig Launcher and Receiver systems. Title Data Sheet for Pig Launcher and Receiver 20 PN 140 MPa DN 250 PIG RECEIVER General Location PS28 Quantity 1 Service Receiving of pigs Tag No. They allow to safely inspect and assess the status of a pipeline in terms of corrosion and scaling without heavy impact of normal pipeline operations.

Pig Launchers and Receivers are installed in pipelines to launch and receive Pipeline Pigs. Of trapped fluid could exceed the design pressure. Both pig launcher and receiver are known as pig trap assemblies.

Welcome To Syschem Controls. 12 This technical specification establishes complementary requirements to be met on design material acquisition manufacturing construction and assembling for Pig Launcher Pig Receiver and Pig LauncherReceiver in PETROBRAS units. Pig Launching Receiving Procedures Pig launchers are used to launch the pig into the pipeline and pig receivers are used to receive the pigs after they have made a successful run.

10-inch by 12-inch 300 pig launcher or pig launch system. 31 Pipeline Design Characteristics. These system packages include the Launcher Receiver Closure Pig Signal.

Pigging is a maintenance procedure used extensively in the oil and gas industry to clean and inspect pipelines carrying refined and unrefined products. Pig signaller will be in the piping design pig launcher or ASME design standards cairnram on 01 Dec 2016 - 0642 AM said. What is a pig launcher receiver Pig launcher receiver are integral parts of a Pipeline.

APC offers complete Pig Launching and Receiving Systems to meet the pipeline operators pigging needs. Pig Launcher Receiver shall be horizontal and the diameter of pig valves shall be equal to the inner diameter of the pipe cleaned. Our launchers and receivers can be designed to accommodate scraper pigs sphere pigs or smart pigs or any combination of the three.

There will be different in different parts of the world but most common is to use the DNV pipeline standards DNVGL-ST-F101 Submarine Pipeline Systems as the governing standard but the code break could require ASME. The reducer should be eccentric for launcher and be concentric for receiver. This would indicate a launcher for a 10-inch pipeline with a 12-inch oversize barrel that allows the operator to slide the pig into launch position.

A pig launcher is a device which uses a pressurized container to shoot a cleaning device pig through the pipeline to perform a variety of functions including cleaning monitoring and maintaining of the pipe. Both Pig launcher and receiver constitutes of the following components. Pig Launcher and Receiver Traps are custom manufactured for sub-sea off-shore and onshore applications.

Considerations for Designing Pig Receivers. One of the Scraper Launchers and Receivers composed of a. Pigs can be used for the cleaning of pipelines.

One of the most effective ways of doing that is with PIGs and the PIG launchers and receivers that facilitate them. An example manufacturer design for a multi-pig launcher system is shown in Figure 3. Pig launcher is used to launch the pig into the pipeline and pig receiver is used to receive the pig after they have made a successful launch.

PR-2801 Specification KPCSK-E-MA-SP-0001 Code ASME BPV Code SectⅧ ASME B313 Painting Design Data Design codes for barrel ASME B 313 ASME BPV Code sectⅧ. The maximum operating pressure could be 740 psi. Multi-pig launcher systems are a design alternative to conventional launcherreceiver systems and reduce pigging emissions by reducing the frequency that launchers and receivers must be vented prior to pig insertion and removal.

Sphere pig launcher portable pig launcher temporary pig launcher Studded Pipeline Pigs subsea automated pig launcher and other Pipeline Pigs Types as per Standards ASME B314 ASME B318 and ASME PED CRN Gost Pressure Vessels Pig Launchers Receivers manufacturer and exporter in Mumbai India. Receiver and Pig LauncherReceiver for PETROBRAS offshore facilities. Permanent supports shall be used to support and restrain the pig traps and these shall be designed to carry the weight of the pig trap system.

This forms a part of the pipeline pigging system. The choice of these pig traps will depend nnmonnn PETROGAS INDUSTRIES. Provisions in the station design should include handling.

740 PSIG Scraper Launchers and Receivers for a Plant in Mexico. 2 Size A typical designation for pig launchersreceivers would be. The process is made possible by launchers and receivers.

A pig receiver is a container or device to receive a pipeline pig out of the pipeline without interrupting the flow. The choice of these pig traps will depend on the type of pig to be run and pipeline design conditions. The launchers and receivers with dimensions of 24 x 30 x 138 long and 10 x 14 x 132 long are designed for 740 PSIG at 170 degrees.

On top of. Pigs can be used for the separation of two products within the same pipelineSweco Fab has over 40 years of experience in designing and manufacturing ASME Pig Launchers and Receivers. The main benefit of this type of maintenance is that is can be carried out without interrupting the process in operation.

Pig signaller will be in the piping design pig launcher or ASME design standards All launchers and receivers have quick opening closures for inserting removing pigs. To perform a suitable selection and arrangement of the devices involved it is required to identify the following parameters.

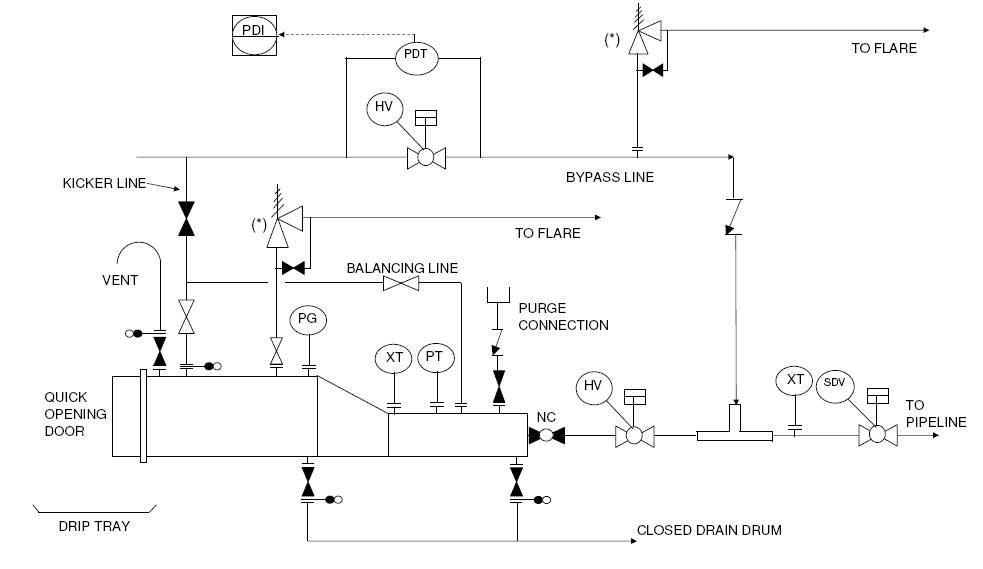

Typical P Id Arrangement For Pig Launchers Pig Receivers Enggcyclopedia

Subsea Pipeline Engineering Pig Trap Pig Launcher Intelligent Pig

Pig Launcher And Receiver Manufacturer And Supplier Reliable Sleeves Engineering Products

General Overview Launchers And Receivers Sure Flow Equipment Inc

Pig Launchers Receivers Jamison Products

Pipeline Pig Traps Receivers And Launchers Enggcyclopedia

What Is A Pig Launcher Receiver For Pipeline Maintenance Metropolitan Engineering Consulting Forensics Services

0 comments

Post a Comment